|

“ |

If we replenish too little, it’s easy to run out of supply and lose some orders that should have come in; if we replenish too much, we’re afraid that supply will outstrip demand and goods will rot in the warehouse." |

This is a problem that has plagued retailers for many years. Especially in today’s fast-paced world, people strive for "speed" at work and "quick fulfillment" of purchasing needs. If retailers are a little slow in delivering goods, consumers may turn to other stores.

What makes it even harder for retailers is managing inventory of perishable goods, such as fresh produce. Nowadays, consumers buy fresh produce for reasons of freshness, health and environmental friendliness. This requires retailers to closely manage the supply chain, such as accurate replenishment and distribution to individual stores, otherwise even the best preservation technology is useless.

|

Image source: ©千库网 |

Supply chain management is linked to business development and economic growth. To solve this seemingly "unsolvable" problem of supply chain management that has long plagued retail enterprises, Professors YANG Yi and ZHOU Weihua from the School of Management of Zhejiang University and their doctoral student HUANG Jingkai, together with Professor Kevin SHANG from Duke University and LI Yuan from Alibaba, have tried to explore "solution strategies" through digital management research.

Click here to access the journal article

|

YANG Yi | 杨翼 School of Management, Zhejiang University |

||

|

|

||

|

|

|

Academic Background: YANG Yi, Vice Dean of the School of Management, Zhejiang University, Professor of Data Science and Management Engineering, and doctoral supervisor. Research interests: Inventory management; revenue management; new retail; blockchain; supply chain management; data-driven decision making You can learn more about Prof. YANG Yi’s academic background here |

|

ZHOU Weihua | 周伟华 School of Management, Zhejiang University |

||

|

|

||

|

|

|

ZHOU Weihua is a professor and doctoral supervisor at the Department of Data Science and Management Engineering, School of Management, Zhejiang University. He is also the director of the International Research Center for Data Analysis and Management, Zhejiang University. Research Interests: logistics and supply chain management, supply chain finance. You can learn more about Prof. ZHOU Weihua’s academic background here |

|

HUANG Jingkai | 黄靖开 School of Management, Zhejiang University |

||

|

|

||

|

|

|

HUANG Jingkai is a PhD candidate in Management Science and Engineering at Zhejiang University, School of Management. Research areas: data-driven decision making, inventory management, statistical learning |

|

DDTA strategy | It Can Make Merchants’ Inventory Decisions More Accurate |

There are many types of distribution systems in the retail industry. If distribution is not involved, losses will be relatively small, even if the wrong decisions are made regarding inventory.

For example, a small greengrocer may occasionally stock too much at once. The worst that can happen is that he/she sells it at a lower price and makes less money.

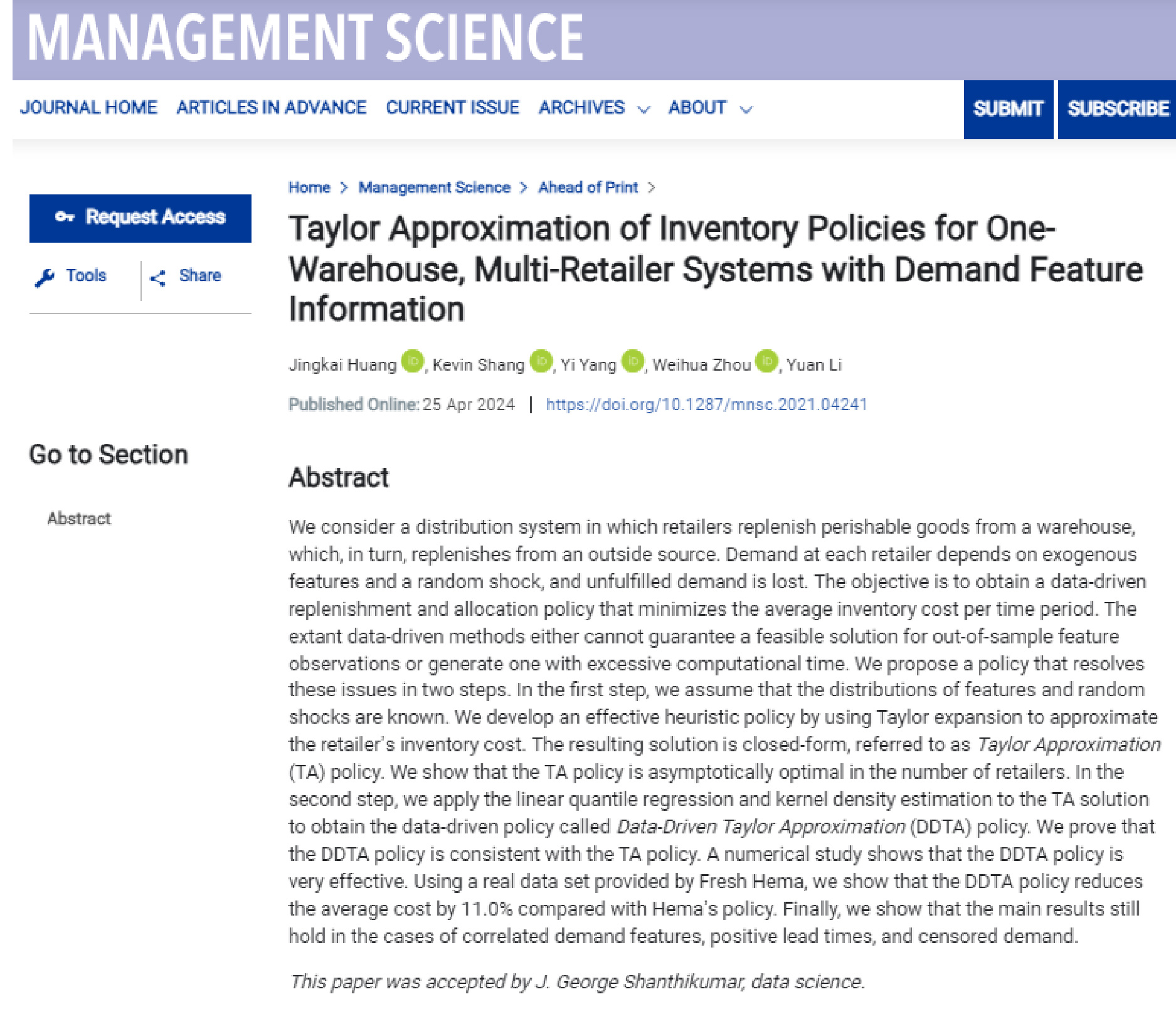

However, if it is a multi-store distribution, especially a distribution system consisting of a central warehouse and several retailers (stores), the loss is huge if the central warehouse inventory management decision makers make a wrong prediction of market demand, resulting in several retailers across the country being unable to replenish goods from the warehouse in time and then losing orders because they cannot respond quickly to market demand.

Especially for large companies using this kind of distribution system, problems in the supply chain mean serious damage to their external brand and image, causing them to lose their original position in the fierce market competition, thus affecting national economic growth.

The research team began by solving the problems of inventory decision making for retailers with one warehouse and multiple stores. By building a data-driven inventory decision making model, they explored an inventory management strategy that can minimize the company’s average inventory cost in each period without knowing the distribution of external demand.

Figure 1 | Schematic diagram of single warehouse-multiple stores inventory model

|

“ |

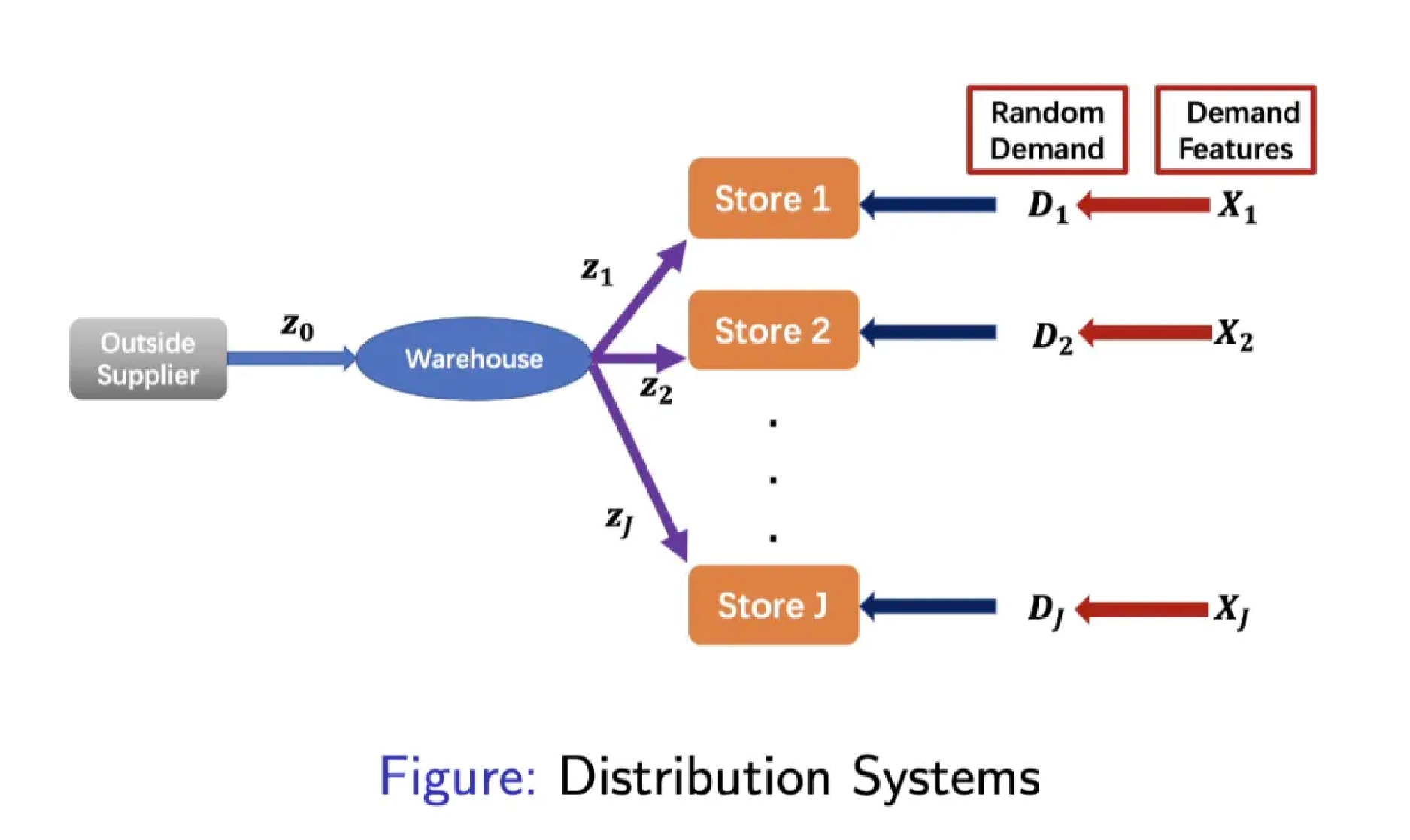

We carried out the investigation in two steps. In the first step, we assumed that the demand characteristics and the distribution of random noise were known, and approximated the retailer’s inventory cost by Taylor expansion (a method of using polynomials to approximate the original function in the calculation) and obtained a Taylor approximation (TA) strategy with a closed-form solution and asymptotically optimal." |

HUANG Jingkai, PhD student and member of the team, also explained:

|

“ |

In the second step, we applied the linear quantile regression and kernel density method to estimate the location parameters in the TA strategy to obtain the data-driven Taylor approximation (DDTA) strategy." |

Figure 2 | Schematic diagram of the sequence of events

“Demand characteristics" refers to some characteristic information related to external market demand, such as weather, temperature, commodity prices, etc. This type of information is information that inventory managers can observe in advance and use as a decision-making tool. "Random noise" refers to the random and unpredictable parts of market demand.

During the calculation process, the research team found that the DDTA strategy can help companies with one warehouse and multiple stores to use information about demand characteristics to replenish and allocate inventory effectively without knowing the distribution of external demand.

|

Image source: ©千库网 |

|

The Researchers Use Real Data to Test the Effectiveness of the Strategy, and the Results Show That This Strategy Can Reduce Storage Costs |

The development of data-driven strategies for inventory management through the creation and calculation of digital models is only one part of this research. Rather, it is crucial to verify the feasibility and effectiveness of the strategy.

To this end, the research team obtained a real data set from Hema Fresh, the first new retail supermarket in China, and used the data to verify the performance of the DDTA strategy in reducing the company’s inventory costs. The results showed that compared with Hema’s current inventory management strategy, the DDTA strategy can reduce the average inventory cost by 11.0%.

Hema’s managers were very pleased with this result, as this research was driven by Hema’s urgent need to "solve the problem of inventory management of perishable goods."

|

“ |

We started this research during our collaboration with HEMA." |

The research team introduced that as a leading new retail platform in China, HEMA’s supply chain network has the typical characteristics of a single warehouse with multiple stores, and that inventory management has long faced the problem of replenishment and distribution, especially for perishable goods such as "fresh daily".

|

Image source: 扬子晚报 |

|

“ |

They hope we can combine the benefits of digital innovation and management discipline to develop a sensible, data-driven “stock replenishment allocation strategy” for their daily fresh products that will help them reduce inventory costs.” |

Today, the DDTA strategy has proven to be "effective" and is showing excellent results. This will not only help Hema Fresh to respond quickly to market demand and achieve sales growth, but will also serve as an inspiration to many new retailers with "one warehouse - multiple stores" characteristics.

|

The Strategy Will Significantly Drive the Development of Digital Retail |

This study is mainly concerned with a data-driven "inventory replenishment and allocation" problem for a retail system with one warehouse and multiple stores that considers information about demand characteristics.

Given the "historical demand data of goods at each store" and the "characteristic product demand data (such as weather, temperature, price, etc. of the day)", how should decision makers formulate strategies for replenishing inventory of goods and strategies for distributing goods to downstream stores after they arrive at the central warehouse?

|

Image source: ©千库网 |

|

“ |

Indeed, previous studies have proposed data-driven strategies to solve such problems, but these strategies either cannot provide feasible solutions for out-of-sample observations of characteristics or take too long to compute.” |

The DDTA strategy developed by the research team has made a breakthrough because it is "simple and practical".

|

- We welcome the research team’s efforts to extend the supply chain model to account for the correlation between demand characteristics, general delivery times, and shortened demand data, which improves the practicability and universality of the model.

- You can read the original article in Chinese here